Alphabetical Index

Browse by Elements

Keyword Search

ASTM Electrolytes

Macro Etchants

Micro Etchants

Named Etchants

New Etchants

Al and Al Alloys

Cu and Cu Alloys

Fe and Fe Alloys

Ni and Ni Alloys

Carbide Etchants

Fluoride Etchants

Nitride Etchants

Other Etchants

Oxide Etchants

Phosphide Etchants

Single Crystal Etchants

Thin Film Etchants

Wafer Etchants

Help

Home

Cracks

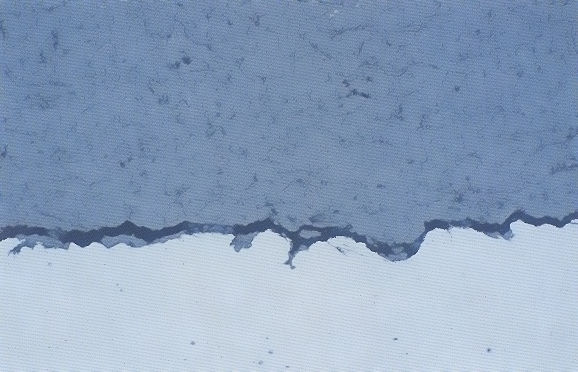

Example: Crack between plasma spray coating and the substrate, Mag. 500x.

Cracks are fractures in brittle materials and materials with different

phases. The energy used to machine the sample is greater than can be

absorbed. The surplus energy results in the cracks. Cracks do occur in

brittle materials and samples with layers. Care has to be taken through-

out the complete preparation process. When cutting coated samples, the

wheel should pass through the layer(s) first, so that the base material

can act as support. Clamping of the sample should be carried out in a

way that no damage can occur. If necessary soft packing between sample

and clamp has to be used. Mounting: for fragile materials, hot compression

mounting should be avoid and cold mountig, preferably vacuum impregnation,

should be used instead. Note: vacuum impregnation will only fill cracks

and cavities connected with the surface.

Reference: Metalog Guide, page 80-81,

Struers A/S, 2610 Rodovre, Dennmark. Note: Image and text by courtesy of Struers A/S company.