Alphabetical Index

Browse by Elements

Keyword Search

ASTM Electrolytes

Macro Etchants

Micro Etchants

Named Etchants

New Etchants

Al and Al Alloys

Cu and Cu Alloys

Fe and Fe Alloys

Ni and Ni Alloys

Carbide Etchants

Fluoride Etchants

Nitride Etchants

Other Etchants

Oxide Etchants

Phosphide Etchants

Single Crystal Etchants

Thin Film Etchants

Wafer Etchants

Help

Home

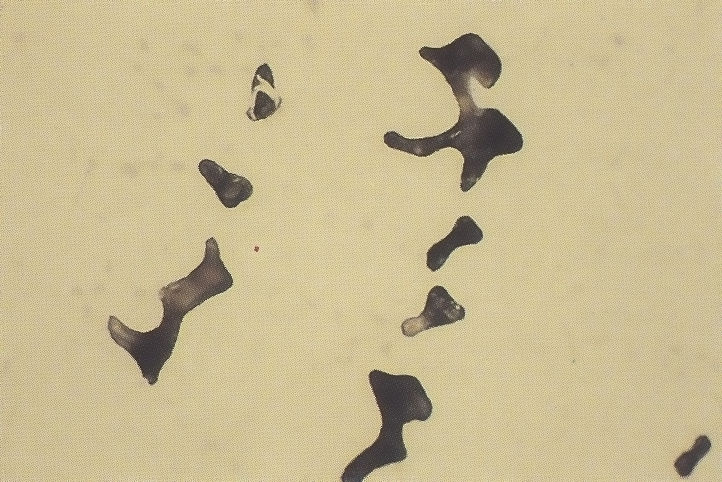

False Porosity

Example: Superalloy after 5 min polishing, Mag. 500x.

Some materials have natural porosity, e.g.cast metals, spray coatings

or ceramic. It is important to get the correct values, and not wrong

readings because of preparation faults. Depending on the properties of

a material, two contrary effects regarding porosity can be seen. Soft

and ductile materials can be deformed easily. Therefore pores can be

covered by smeared material. Hard, brittle materials often get fractured

at the surface during the first mechanical preparation steps. Contrary

to the ductile material, where the initial porosity seems to be low

and the pores have to be opened, brittle materials seem to have a high

porosity. The apparent fracturing of the surface has to be removed.

Reference: Metalog Guide, page 82-85,

Struers A/S, 2610 Rodovre, Dennmark. Note: Image and text by courtesy of Struers A/S company.