Alphabetical Index

Browse by Elements

Keyword Search

ASTM Electrolytes

Macro Etchants

Micro Etchants

Named Etchants

New Etchants

Al and Al Alloys

Cu and Cu Alloys

Fe and Fe Alloys

Ni and Ni Alloys

Carbide Etchants

Fluoride Etchants

Nitride Etchants

Other Etchants

Oxide Etchants

Phosphide Etchants

Single Crystal Etchants

Thin Film Etchants

Wafer Etchants

Help

Home

Smearing

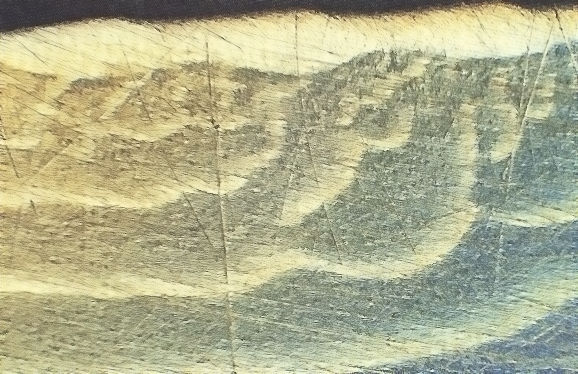

Example: Smearing on soft ductile steel, Mag. 15x, DIC.

The plastic deformation of lager sample areas is called smearing.

Instead of being cut, the material is pushed, moved across the surface.

The reason is an incorrect application of abraive, lubricant or polishing

cloth, or a combination of these, which makes the abrasive act as if it

was blunt.There are three possibilities to avoid smearing: 1. Lubricant:

check the amount of lubricant, smearing often occurs at too low a

lubricant level. If increase amount of lubricant. 2. Polishing cloth:

Due the high resilience of th cloth the abrasive can be pressed too

deep into the cloth and can not cut. Change cloth with lower resilience.

3. Abrasive: the diamond grain size might be to small, the prticles can

penetrate into the material and because of that can not cut.

Reference: Metalog Guide, page 70-71,

Struers A/S, 2610 Rodovre, Dennmark. Note: Image and text by courtesy of Struers A/S company.