Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Highly deformable MnS inclusion and non-deformable calcium aliminate inclusion

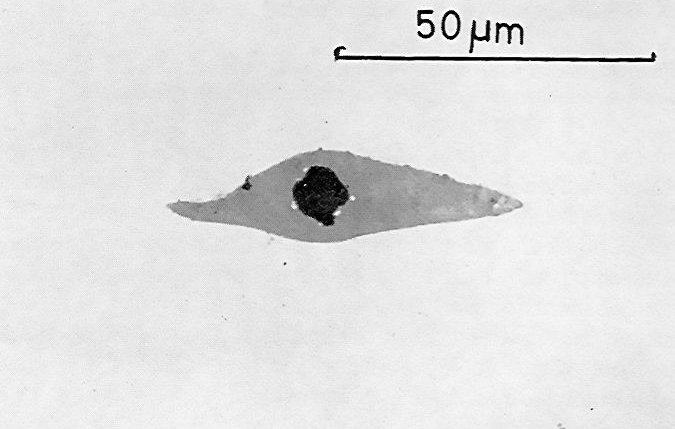

Figure 1: Highly deformable inclusion (v=1) in rolled steel. Crack fromation at the metal/inclusion interface. Scale bar: 50 µm.

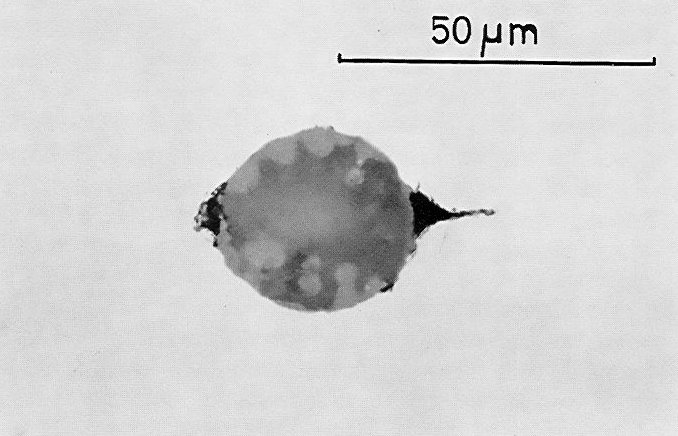

Figure 2: Non-deformable inclusion (v=0) in rolled steel with conical gap in steel phase. Scale bar: 50 µm.

Inclusion name: MnS, calcium aluminate

Record No.: 77

Inclusion formula: MnS

Inclusion type (Macro/Micro/Nano): Macro

Inclusion type (Exogenous/Indigenous): Indigenous

Inclusion classification: Sulfide

Inclusion composition in weight %: No data

Sample: Laboratory 6 kg ingot of electrolytic iron, molten in a high frequency induction furnace in magnesia crucibles and deoxidized with manganese, silicon manganese and silicon.

Steel composition in weight %: (First) 0.006-0.010% C, 0.004-0.006% Si, 0.003-0.005% S, nil P, 0<Mn<1.25. (Second) 0.02-0.007% C, nil Mn, 0.001-0.006% P, 0.002-0.006% S, 0.002-1.175% Si.

Note: v - is index of deformability. Fig. 1: The eliptically deformed inclusion in the steel in MnS with a small nucleus of calcium aluminate. No discontinuities occur between the inclusion and the steel phase. Fig. 2: The spherical inclusion is a calcium aluminate, which was not deformed at the rolling temperature of the steel. The rolling direction is indicated by the cavity. White areas in the inclusion are MnS precipitates at the inclusion surface.

Reference: Not shown in this demo version.