Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Thermal stresses near nonmetallic inclusions and wear parts near nonmetallic inclusion in wheel steel

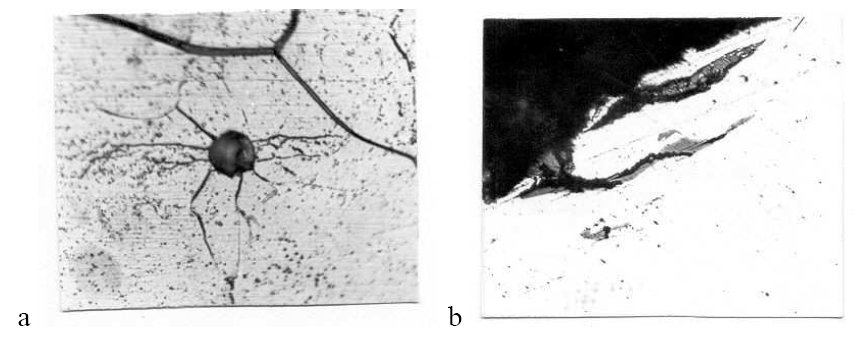

Figure 1: Thermal stresses near nonmetallic inclusions (a) and wear parts near nonmetallic inclusion (b), Mag. 600 X.

Inclusion name: Inclusion

Record No.: 856

Inclusion formula: No data

Inclusion type (Macro/Micro/Nano): No data

Inclusion type (Exogenous/Indigenous): No data

Inclusion classification: No data

Inclusion composition in weight %: No data

Sample: Wheel steel

Steel composition in weight %: No data

Note: It is well known that formation of defects of many types during railway wheels service somehow or other is connected to nonmetallic inclusions in wheel steel.

Microbreakes connected with nonmetallic inclusions have different origin. The first one is “deformational”, the second is “thermal” and the third is “hydrogenous”. The objective

of this work is the study of nature of microbreaking in wheel steel relative to nonmetallics. Mechanisms of microbreaking of all types near different nonmetallics had

been investigated and their influence on safety threshold of railway wheels had been analyzed herein.

Thermal microbreaks (voids or ductile cracks) are generated either during steel cooling after hot deformation of wheel steel or wheel cooling during thermal hardening. This phenomenon is associated with difference in thermal compression coefficient between inclusion and matrix that generates thermal stresses near nonmetallic inclusions (Fig. 1a). The same factor is significant during formation of thermal stress fatigue and, as consequence, microbreaking of wheel in service thermal cyclic loads.

Plastic shifts near tread surface are developing during wheel service and if inclusions are located

in this area they cause cracks and wear parts formation. These are also microbreaks of deformational

origin. Ready to use wheels inherit inclusions distribution from ingot. During service life wheels are

running in severe loading conditions, undertaking alternating loads, subjecting to impacts from higher

or lower and frequently cyclic changing temperatures. Reliability and durability of railway wheel are

connected with its resistance for cracking incipiency and development. Near inclusions, in conditions

of alternating, cyclic and constant loads and temperatures, local stresses field occurs inevitably, and its

magnitude depends on the type of loading, size and form as well as inclusions interference. For

example, under cycling loading, stresses near inclusions reach the value of steel yield stress. Process

of accumulation of such stresses causes the incipiency of cracks fatigue near inclusions (Fig. 1b).

Additional links: Not shown in this demo version.

Reference: Not shown in this demo version.