Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

(Ti, Ca)-oxide in 409L stainless steel

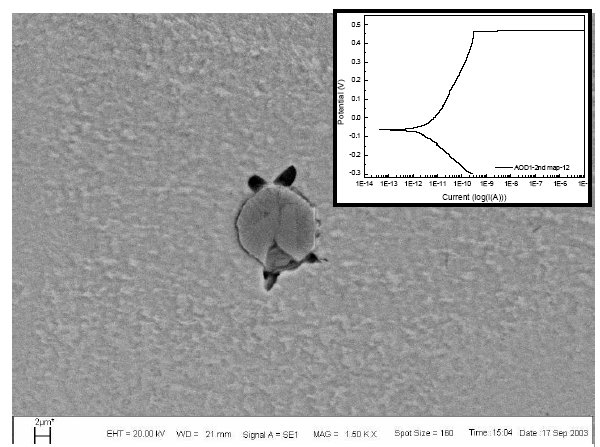

Figure 1: SEM images of pitted inclusions in 409L AOD alloy after potentiodynamic test in 0.5 M NaCl solution and its potentiodynamic curve. Scale bar: 2 µm.

Inclusion name: (Ti, Ca)-oxide

Record No.: 864

Inclusion formula: No data

Inclusion type (Macro/Micro/Nano): Micro

Inclusion type (Exogenous/Indigenous): Indigenous

Inclusion classification: Oxide

Inclusion composition in weight %: No data

Sample: 409L stainless steel

Steel composition in weight %: No data

Note: It is well documented that manganese sulfides (MnS) among non-metallic inclusions act as initiation sites for pitting corrosion in commercial stainless steels. However, independent effects of other non-metallic inclusions such as oxide and nitride on localized corrosion in stainless steel have hardly investigated because of the low lateral

resolution of the standard electrochemical experiment methods. Traditional macroscopic electrochemical behavior is simply the sum of the contributions of the different grains

or phases, multiplied by their individual degree of coverage. A new electrochemical device, the capillary-based microdroplet cell gives facilities for micro-electrochemical

investigations at high resolution.

It was found from the micro-probe technique using a micro droplet cell that pitting corrosion initiated at the interface between round (Ti, Ca)-oxide and matrix (Fig. 1). On the other and, Ti-nitrides in VOD alloy were inactive to pitting corrosion. For 409 alloy refined by AOD, the resistance to pitting corrosion increased linearly with Ti content in the (Ti, Ca)-oxide, but decreased with Ca content in the (Ti, Ca)-oxide.

Reference: Not shown in this demo version.