Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

MC and M23C6 carbides in Armour steel

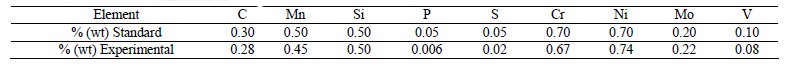

Table 1: Class 2 armour steel compositions according to MIL MIL-A-11356F and used in experiments.

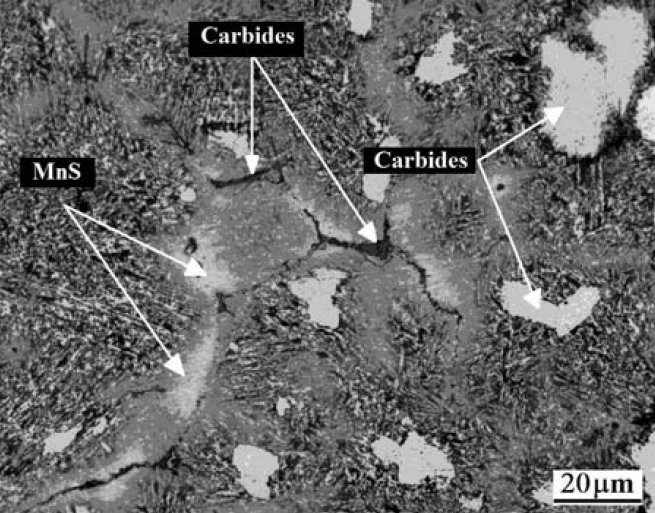

Figure 1: Microstructure of as-cast specimen. Scale bar: 20 µm.

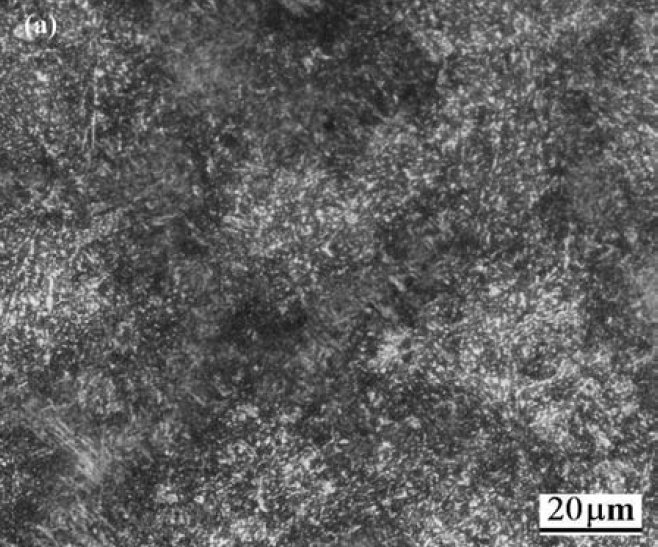

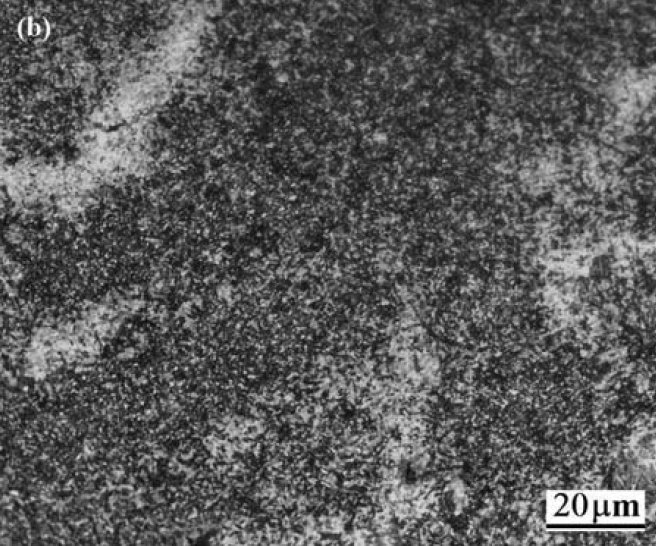

Figure 2: Microstructures of HAZ of parts single pass welded

(a) and pre-heated/single-pass welded (b). Scale bars: 20 µm.

Carbide name: MC, M23C6

Record No.: 1061

Carbide formula: MC, M23C6

Carbide type: MC, M23C6

Carbide composition in weight %: No data

Image type: LM

Steel name: Armour steel

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: Armour steels

Steel composition in weight %: See the table 1.

Heat treatment/condition: In this research, Class 2 armour steel parts were welded using

single-pass and pre-heated/single-pass conditions to examine

optimal welding parameters in relatively thin parts. Armour steel

parts were produced in high frequency induction furnace and cast

into resin-bonded sand mould. Specimens were then machined

into 5 x 10 x 100 mm dimensions, cut into two pieces (5 x 10 x 50 mm) and gas tungsten arc welded (GTAW) using a low-alloyed

high-strength steel filler rod (AWS A5.5:E 8018-B2). Chemical compositions of typical and cast armour steels were

given in Table 1. Test parts were welded using 70 A current and 10 l/min argon

flow. (A) parts were single pass welded. (B) parts were pre-heated

to 100°C and then single pass welded. Welded specimens were

investigated using optical microscopy and Vickers hardness tests.

Optical micrography was used to characterise transition sites of

base metal, HAZ and weld zone. Hardness test was conducted to

characterise homogeneity of welding in terms of mechanical

properties.

Note: Purpose: In this study, microstructural and mechanical evaluations of class 2 armor steel after single-pass and

pre-heated/single-pass welding were investigated to reveal the effect of pre-heating on heat affected zone (HAZ)

in thin armor steel parts.

Design/methodology/approach: In this research, class 2 armor steel parts were welded using single-pass

and pre-heated/single-pass conditions to examine optimal welding parameters in relatively thin parts. Welded

specimens were investigated using optical microscopy and Vickers hardness tests. Optical micrography was used

to characterise transition sites of base metal, HAZ and weld zone. Hardness test was conducted to characterise

homogeneity of welding in terms of mechanical properties.

Findings: The results have shown that pre-heat/single-pass welding of armor steel could provide homogeneous

hardness distribution along welding region. Similar microstructures and mechanical properties were found in base

metal and HAZ.

Practical implications: Armor steel was succesfully welded using GTAW without any defects either in weld

seam or HAZ.

Segregation is generally inevitable in castings which results in

degradation of mechanical properties. Armour steels without

annealing have significantly MnS segregated sites. In present

study, no heat treatment was conducted in weld region to examine

the characteristics of HAZ. Microstructure of as-cast test parts

was given in Fig. 1. Previous studies have shown that approximately 2% M23C6

and 0.5% MC carbide formation. Microstructures of HAZ of parts

single-pass welded (A) and pre-heated/single-pass (B) were given

in Fig. 2a and Fig. 2b. Fine grained microstructure was resulted

due to rapid cooling. However higher hardness alone is not a

significant property in steels used in armoury equipments since it

does not have direct influence in fracture strain.

Links: No data

Reference: Not shown in this demo version.