Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Carbon Extraction Replica Preparation

The carbon extraction replica technique was very useful for the

identification or counting of carbide phases in the metallic system. The main

advantages of replicas over foils were that they eliminated any effects due to

the steel matrix and thus enabled the chemical composition of the carbides to

be measured more accurately, and problems associated with working with a

magnetic specimen in the TEM were avoided.

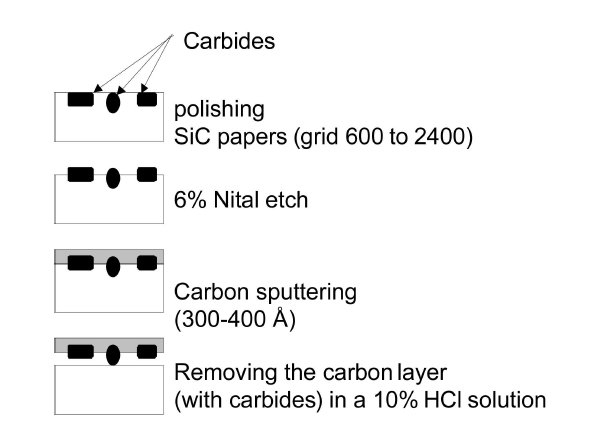

Figure 1: a) Initial sample, b) sample after chenical etching, c) carbon deposit and d) final replica.

Single stage carbon extraction replicas were prepared using the method

described by Smith and Nutting (1957) from surfaces prepared as for optical

microscopy. For initial etching of the sample (before carbon coating), a 2% nital

solution (or Villela) was used to give a light etch (carbides just being resolved by optical

microscopy). A piece of acetate was dipped in acetone and then put on the

specimen after etching as stripping cleaning. The mounting bakelite was well

masked before carbon coating. The specimen was placed in a carbon

evaporator with a high vacuum. It is

important to ensure that the surface of the mounted specimen is clean and free

from grease to give a good adhesion of the deposited carbon film (colour bluebrown).

Carbon is deposited from a height of 100 mm directly above the

specimen surface to obtain as even a coverage as possible.

The etchant used for releasing the carbon film from the surface of the

specimen was a 6% nital solution (or Villela). The specimen was scored with a sharp

blade into squares approximately 3 mm across to allow reasonable access for

the etchant to bare metal surface, and to ensure that the carbon replica pieces

would be of suitable size. As soon as the carbon layer had peeled off the metal

surface, the specimen was washed in methanol, and the fragments of carbon

layer were floated using the surface tension provided by a 20% methanol and

80% distilled water mixture. Each replica was then collected onto a 3 mm

diameter, 200 square mesh copper grid and was ready for analysis in the TEM.