Alphabetical Index

Browse by Elements

Keyword Search

ASTM Electrolytes

Macro Etchants

Micro Etchants

Named Etchants

New Etchants

Al and Al Alloys

Cu and Cu Alloys

Fe and Fe Alloys

Ni and Ni Alloys

Carbide Etchants

Fluoride Etchants

Nitride Etchants

Other Etchants

Oxide Etchants

Phosphide Etchants

Single Crystal Etchants

Thin Film Etchants

Wafer Etchants

Help

Home

Aluminium and alloys - Restoration of obliterated marks

Material Name: Aluminium and alloys

Recipe No.: 12058

Primary Chemical Element in Material: Al

Sample Type: Bulk

Uses: Macrostructure

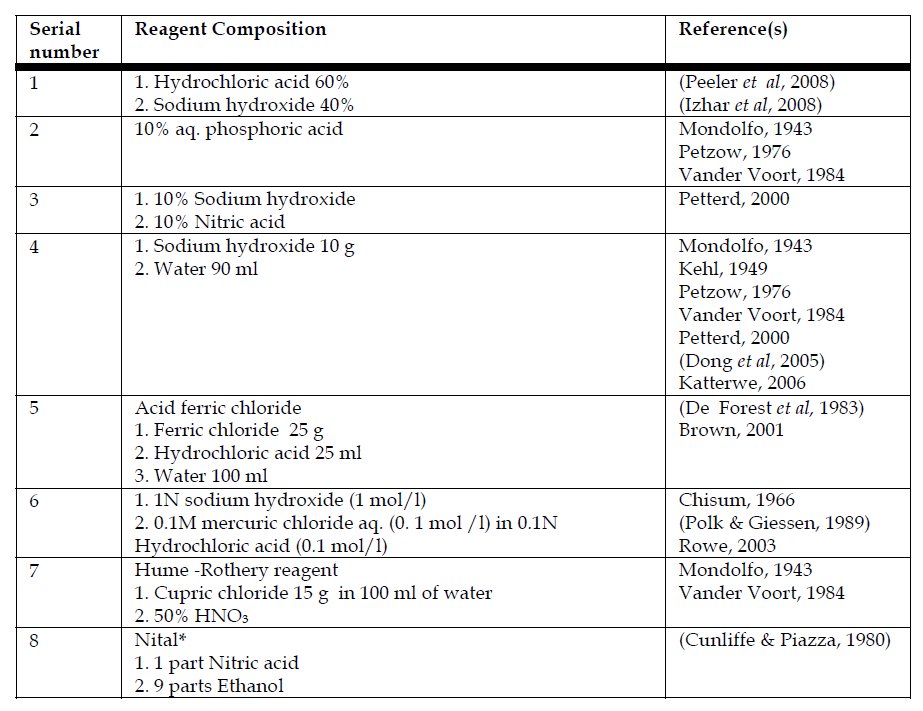

Etchant Name: See the table

Type (Macro/Micro): Macro

Etching Method: Chemical

Etchant (Electrolyte) Composition: See the tables 1 and 2.

Procedure (Condition): See the tables 1 and 2.

Note: A problem of common occurrence in forensic science is the restoration of obliterated serial

numbers on the chassis and engine of stolen motor vehicles, firearms, jewellery, valuable

tools, and machinery (Nickols, 1956; Wolfer & Lee, 1960; Jackson, 1962; Cunliffe & Piazaa,

1980; De Forest & Gaensslen, 1983; Schaefer, 1987; O’Hara & O’Hara, 1994; Moenssens et al

(1995); Heard, 1997; Petterd, 2000; Lyle, 2004; Katterwe, 2006; Seigel, 2007; Mozayani &

Noziglia, 2006; Jackson et al (2008); Levin, 2010). Serial numbers or other markings, which

are unique to that particular item, are usually marked on the above metal surfaces during

the manufacturing process. Criminals alter or obliterate these identification marks during

thefts or other illegal uses in order to prevent their identity. On many occasions a fraudulent

number would be introduced after removing the original one. In abandoned vehicles all

serial numbers are verified in order to detect alterations in the identity of the vehicle

(Svensson et al, 1981). Sometimes the serial numbers on firearms are removed more

professionally making it hard to distinguish whether the numbers are original or not

(Shoshani et al, 2001). Restoration of the original obliterated numbers provides important

forensic evidence in order to return the items to the owner and also to follow up the criminal

proceedings against the perpetrator. In cases involving firearms the recovered numbers

provide an important investigative lead. The history and the ownership of the firearm can be

obtained only from the serial number. In forensic practice a few experimental techniques are

being used successfully to restore the obliterated serial numbers on the above surfaces. The

methods include: chemical etching, heat treatment, magnetic particle, ultrasonic cavitation and relief

polishing (Nickols, 1956; Polk & Giessen, 1989; Maxwell, 1993; Heard, 1997; Hogan et al, 2006;

Katterwe, 2006). Nondestructive methods such as hardness testing, magnetic imaging, x-ray

imaging, eddy current, infrared imaging, scanning acoustic microscopy, electron channeling

contrast and thermal wave imaging are also proposed (Hogan et al, 2005; Katterwe, 2006;

Klees, 2009). However, chemical etching is most popular because it is sensitive, easy to apply

on any size and also kind of object and reproducible. Etching can be applied on all metal

surfaces including precious ones (Crowe & Smith, 2005).

Reference: From the book, Aluminium Alloys, Theory and Applications, Edited by Prof. Tibor Kvackaj, 2011, R. Kuppuswamy, Metallographic Etching of Aluminium and Its

Alloys for Restoration of Obliterated Marks in Forensic Science Practice and Investigations, www.intechopen.com, 2019, pp. 331-352.

Table 1: Etching reagents used to restore erased engraved marks on aluminium and its alloy

surfaces.

Click the table to enlarge the data.

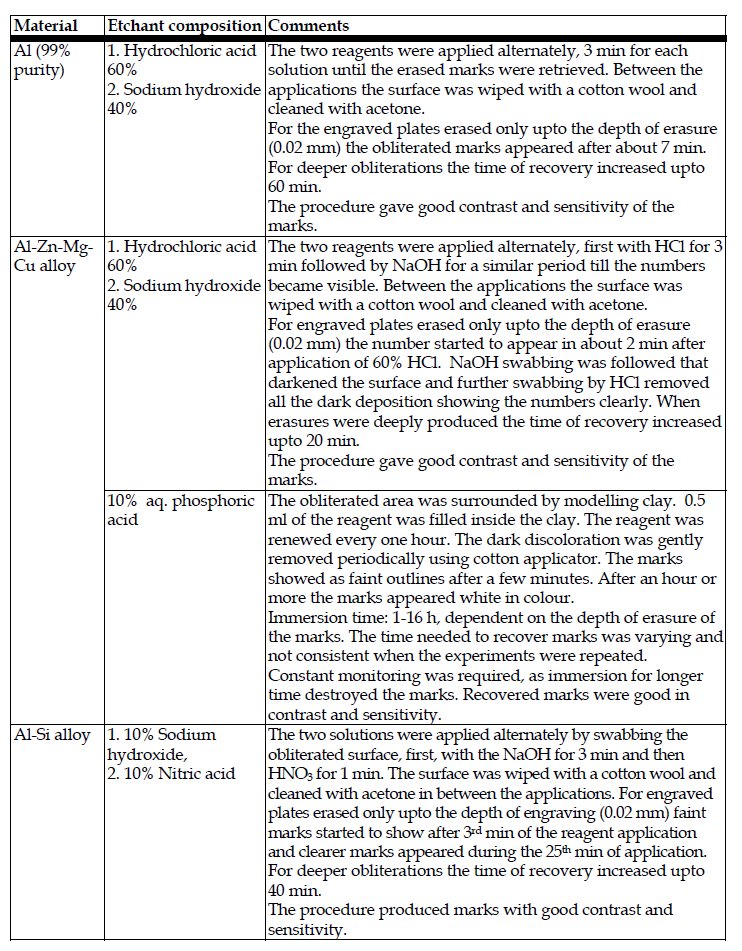

Table 2: Reagents for etching Al (99% purity), Al-Zn-Mg-Cu and Al-Si alloys for restoration

of obliterated marks. The reagents were sensitive enough to recover the marks on the

engraved plates erased down 0.02 to 0.04 mm below the engraving depth. The marks

produced by the reagents were also reproducible.

Click the table to enlarge the data.