Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Al2O3 cluster inside of bubble in ultra low carbon steel

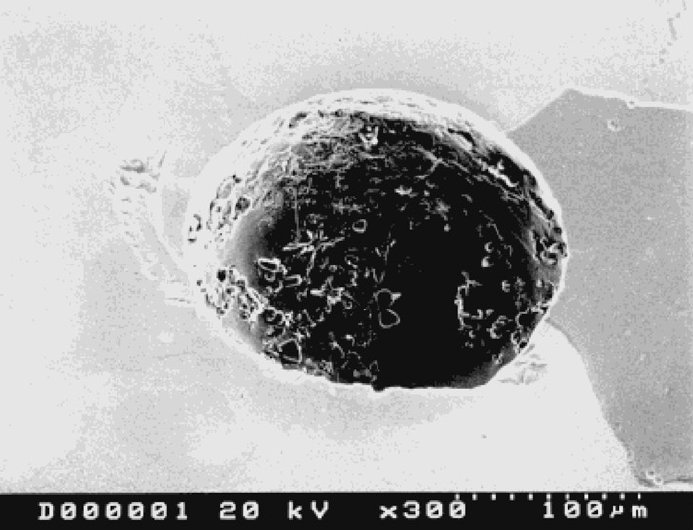

Figure 1: Al2O3 cluster inside of bubble. SEM, scale bars: 100, 30 µm.

Inclusion name: Al2O3 cluster

Record No.: 859

Inclusion formula: Al2O3

Inclusion type (Macro/Micro/Nano): Micro and macro

Inclusion type (Exogenous/Indigenous): Indigenous

Inclusion classification: Oxide

Inclusion composition in weight %: No data

Sample: Ultra low carbon steel

Steel composition in weight %: Low S: <0.002% C, 0.22% Mn, 0.018% P, 0.006% S, 0.037% Al-s, 0.047% Ti, <0.005% Nb, 0.002% N. High S: <0.002% C, 0.18% Mn, 0.018% P, 0.018% S, 0.029% Al-s, 0.049% Ti, <0.005% Nb, 0.003% N.

Note: The sliver defects which occur easily on ultra low carbon steel sheet are the most harmful defects, especially to automobile outer panel products. There may be many causes of the sliver defects such as nonmetallic inclusions, bubbles, surface cracks and inner cracks. However, crack formation is not a serious problem in continuously cast ultra low carbon steel because of its good ductility at high temperatures. Therefore, it is important to reduce the amount of nonmetallic inclusions and bubbles just below the slab

surface. Electro-Magnetic Stirring in the mold (M-EMS) is an effective tool to remove such bubbles and reduce the amount of the sliver defects, although the effects of M-EMS on the reduction in sliver defects are influenced by the chemical composition of steel, especially by the sulphur content.

In order to improve the surface quality of the production of ultra low carbon steel sheet used for automobiles, it is important to reduce the nonmetallic inclusions and bubbles

(blowhole defects) which exist just below the surface of continuously cast slab. Al2O3 clusters are often found on the inner surface of a bubble as shown in Fig. 1.

Reference: Not shown in this demo version.