Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Troilite

Chemical formula: FeS

Modifications: Several modifications of FeS exist, crystallographically closly related but differing slightly in composition. The most common modifications, pyrite (FeS2) and marcasite (FeS2).

Melting point: 1190oC

Density: 4.77 g/cm3

Microhardnes: FeS is reported to be harder than MnS (Kiessling and Lange, 1964)

Hardness (Moh's): 3.5-4

Colour: FeS has a yellow ochre colour in the optical microscope. It is anisotropic and therefore is active in polarized light, whereas the cubic MnS is inactive.

Crystal system: Hexagonal

Cell dimensions: a=3.43 A, c=5.68 A

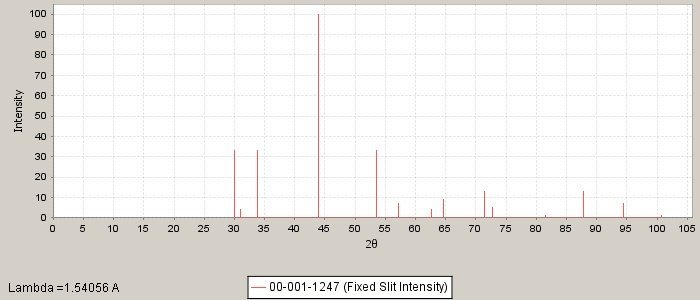

PDF number: 00-001-1247

ICSD number: 035005

Note: Fe(1-x)S with lower sulphur content (x=0) has a hexagonal lattice and is superstructure of the NiAs lattice. This phase as a mineral has the name troilite (FeS). For higher sulphur content (increasing x-values) the crystal structure of Fe(1-x)S cahnges to the more simple basic structure of NiAs, and the pyrrhotite minerals usuallyhave this crystal strcture. FeS inclusions may have a Cr content of up to 20%, They have also been found with Ti and V in solid solution, whereas the solid solubility for Mn is reported to be low. However, they found a solid solubility of about 7% of Mn in FeS. The solid solubility of C and O in FeS is low. No carbosulfides or oxysulfides of iron have been reported, but two-phase inclusions with FeS and FeO or with FeS and Fe-silicate are common. The formation of hot-shotness: Sulphur is soluble in liquid iron but the solubility us very low in the solid iron phase. When iron solidifies, sulphur therefore precipitates as FeS, either as primary FeS dendrites or as eutectic constituent with iron. This eutectic has a low melting point 988oC and the melting point is decreased by the influence of oxygen.For instance the FeO-FeS eutectic has a melting point about 988oC. Sulphur therefore segregates to those part of the ingot which are the last to solidify and the grain boundaries of these parts will be rich in FeS. The sulfide phase may either from primary FeS or be present in different eutectics. If the ingot is reheated to temperatures in the range of 980-1200oC a liquid phase my be formed in the grain boundaries. This may cause cracking of the iron, starting in the grain boundaries, if the iron is plastically deformed. This phenomenon is called hot-shortness.

In modern steels formation of FeS is avoided by Mn additions and FeS is not a common phase in steels.