Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Premature tempering accounted for

the cracking during treatment of this

21-in.-OD ring die - Tool steels - Fractography - Heat treatment defects

Figure 1: Premature tempering accounted for

the cracking during treatment of this

21-in.-OD ring die, a portion of which

is illustrated. Made of high-carbon,

high-chromium tool steel, it was apparently much hotter than 200 F when

the air-quench was halted. The die

was put into the tempering furnace

before the hardening transformation had progressed appreciably. In this grade of steel,

such transformation does not even begin until it has cooled to about 400 F.

The temperature reached in tempering, about 925 F, does not transform this steel readily,

so it was still unhardened when the tempering operation was completed. Cooling in air

following removal from the tempering furnace again started the hardening transformation, but the die was then water-cooled—a much too drastic procedure. The intent wasto cool it so that it could be handled for hardness testing. Stresses were set up and cracking

resulted.

If this die had not been water-cooled following the temper, but had been allowed to

cool to room temperature in air, and had then been re-tempered, it is probable that no

trouble would have occurred.

The original error, of course, was removal of the die from the quench too soon. The second error was cooling in water.

A double temper would have corrected the trouble caused by the original error.

Microscopic examination furnished the clue which brought to light the faulty procedure.

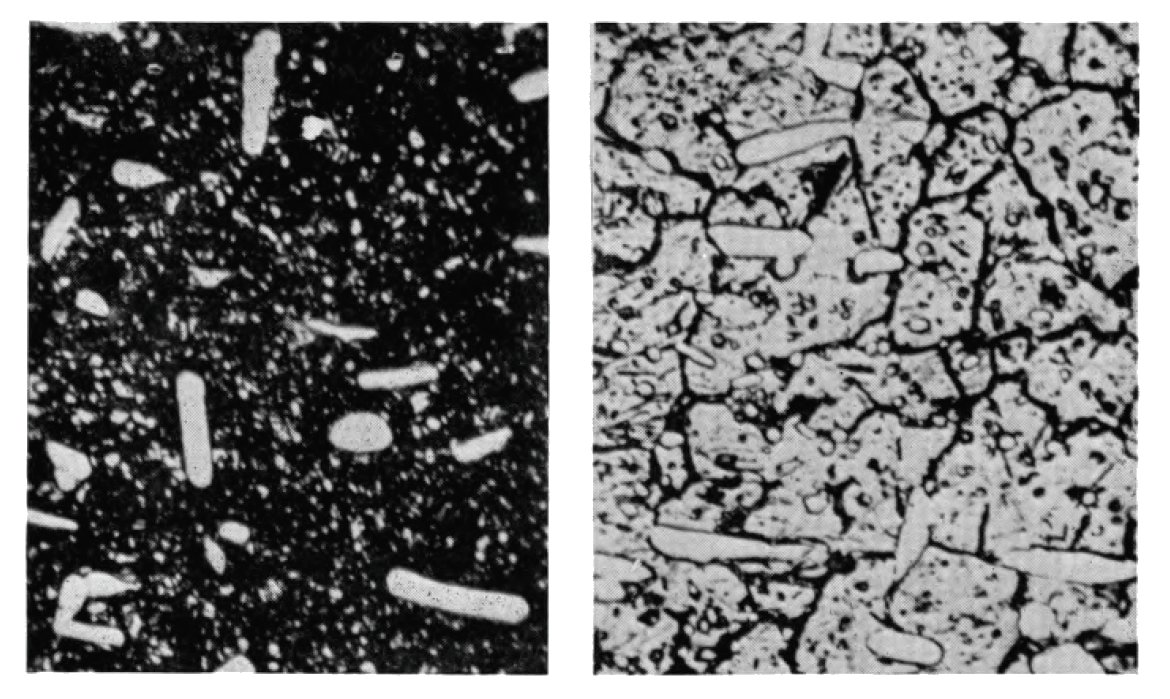

Note the microstructures on Fig. 2.

Figure 2: Left: Normal microstructure (7O0x magnification) of hardened-and-tempered high-carbon, high-chromium steel showing carbides in a tempered martensitic matrix. Right: Structure of ring die shown on Fig. 1. This structure showing carbides in untempered

martcnsitic matrix, is typical of as-quenched steel of this grade and indicates that the

die did not respond to tempering because of the incomplete quench.

Defect name: Cracks

Record No.: 2899

Type of defect (Internal/Surface): Internal, surface

Defect classification: Fractography, heat treatment defects

Steel name: Tool steel

Steel composition in weight %: No data.

Note: No data.

Reference: Not shown in this demonstration version.