Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Ejection die - Tool steel defects

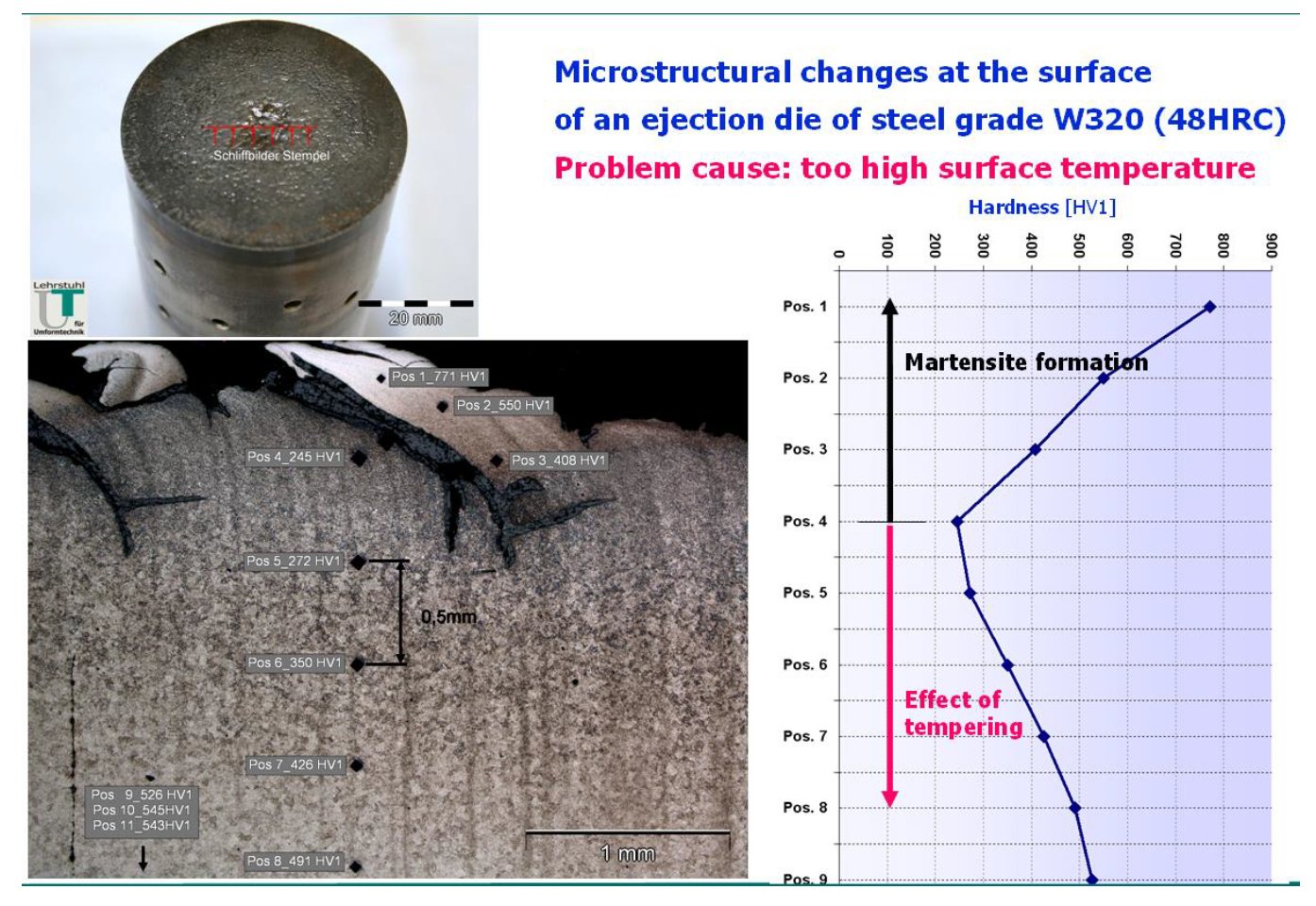

Figure 1: Damage and microstructure of an ejection die after 17000 strokes.

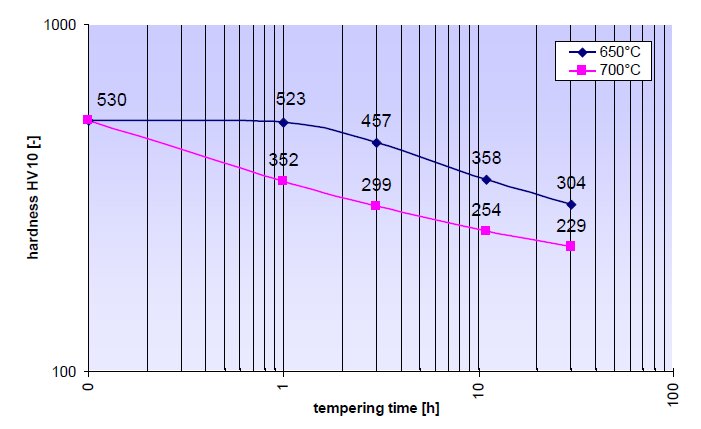

Figure 2: Hardness loss due to tempering of hot working tool steel W320.

Defect name: No data.

Record No.: 3232

Type of defect (Internal/Surface): Internal, surface

Defect classification: Tool steel defects

Steel name: Tool steel

Steel composition in weight %: No data.

Note: In this similar case, an ejector of a horizontal high speed forging machine shows a

complete different surface appearance at the contact area, as shown in Figure 1 together with

the microstructural section and hardness profile from the outer surface to the core. The

morphology gives some evidence of overheating. The microstructure in the outer region is

martensitic, and the hardness profile shows, that at position 4, there is a transition from an

over-tempered structure to a newly formed martensitic layer.

Due to the metallic contact the surface temperature can reach up to 700°C. It is the mean

temperature between preheating and forging temperature under the assumption that the

thermo-physical properties of the die and the forged part materials are similar. This can be

verified by some annealing tests using different temperatures and times. Figure 2 shows such

results and compared to the data in Fig.1, it can be confirmed that the above mentioned

contact temperature has been exceeded at the interface. Only intermediate layers having a low

thermal conductivity like Nickelbase-alloys or nitriding are good counter-remedies to lower

the contact temperature.

Reference: Not shown in this demonstration version.