Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

4.7 t ingot made of 18Kh2N4VA steel - Ingot defects

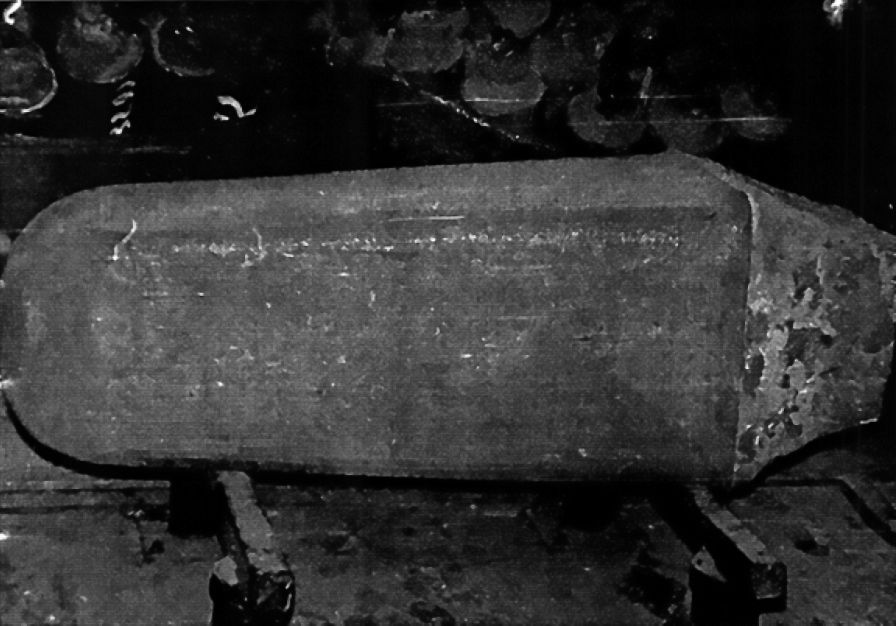

Figure 1: 4.7 t ingot made of 18Kh2N4VA steel.

Figure 2: Dark shell in a 4.7 t ingot made of 18Kh2N4VA steel.

Defect name: No data.

Record No.: 3342

Type of defect (Internal/Surface): Surface

Defect classification: Ingot defects

Steel name: 18Kh2N4VA steel

Steel composition in weight %: No data.

Note: The problems related to improving the process of top casting of complexly alloyed and high.alloy

steels and alloys are considered. To increase the ingot surface quality and the ingot.to.product yield, a new

method of top casting of steels and alloys is proposed. In this method, a floating shield made of a light refrac.

tory material is placed in a mold and protects the mold surface against metal splashes.

The first experiments of casting 18Kh2N4VA steel

into 4.7 t ingots performed with this technique

showed that the ingot surface is defectless (Fig. 1) and

that a dark shell forms upon rolling (Fig. 2).

This shell results from the fact that some drops

stuck to the inner shield walls to form a shell during casting; this shell left the shield, penetrated into the

metal volume, and had no time to dissolve completely.

To remove this shell, we preliminarily deposited an

antistick coating made of a mixture of 85% graphite

and 15% clay onto the inner shield surface in order to

prevent sticking of metal drops to the inner shield sur.

face and their penetration into the ingot body, which

was supported upon rolling of ingots. No defects in the

ready products were detected.

Another advantage of this casting method consists

in the fact that the shield occupying the upper position

serves as an additional heat.insulating gasket that allows a metal to be held in the liquid state in the sink.

head for a longer time, which decreases the number of

shrinkage defects.

In conclusion, note that it was easy to implement

this technology of top casting of high.alloy steel into

a mold with a protective shield. This technology

makes it possible to produce ingots with a good sur.

face, which excludes the costs of its conditioning,

and the decrease in the heat removal from the head of the ingot leads to a decrease in the cutting losses by

3–5%.

Reference: Not shown in this demonstration version.