Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

A typical circumferential crack formed during the open-die forging - Ingot defects

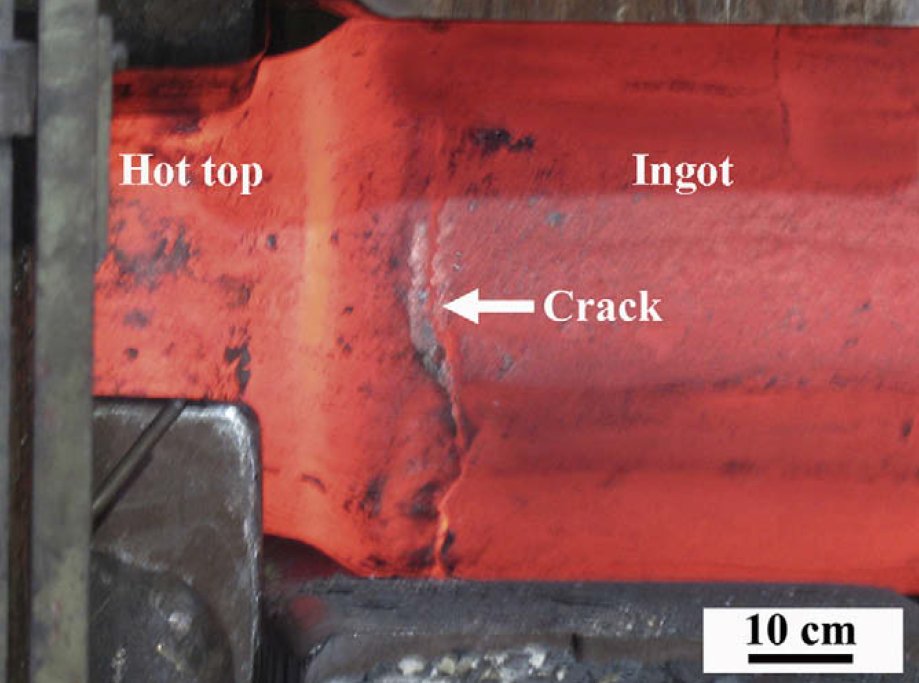

Figure 1: A typical circumferential crack formed during the open-die forging of a 6-ton

low alloy steel ingot.

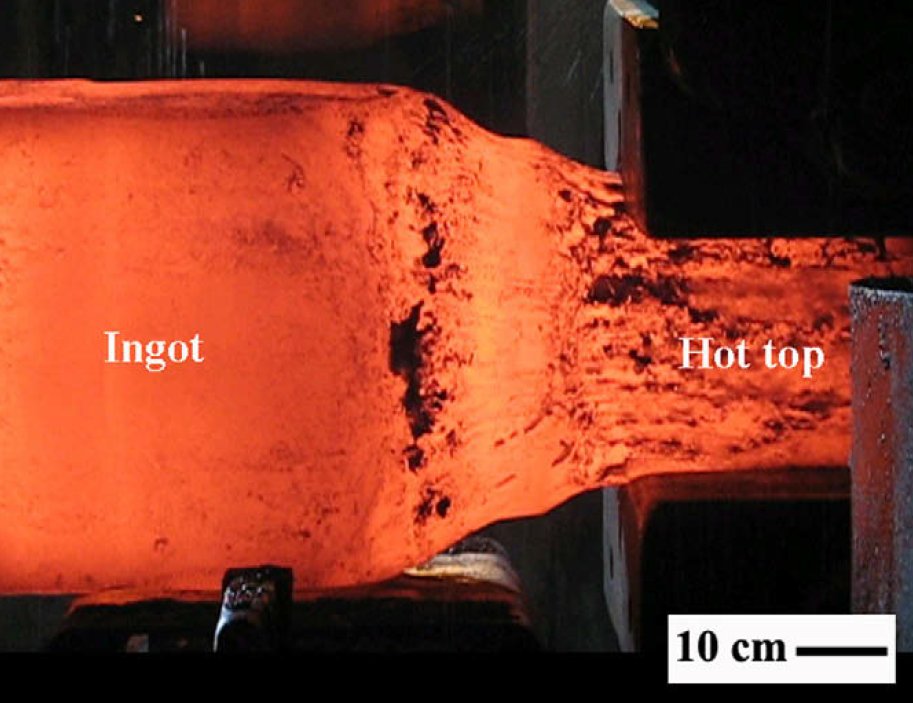

Figure 2: Photograph of a 6-ton low alloy steel ingot during the open-die forging the

similar ingot. Note that no crack is formed in the intersection of the hot top (right)

and ingot (left).

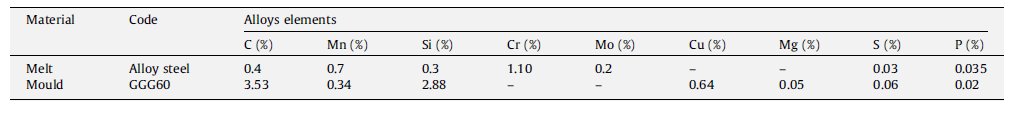

Table 1: Chemical compositions of ingot and mould.

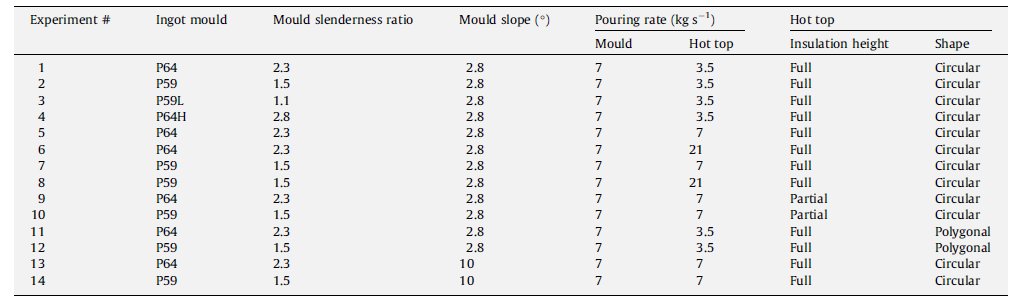

Table 2: Experimental conditions used for the simulations.

Defect name: Crack

Record No.: 3343

Type of defect (Internal/Surface): Surface

Defect classification: Forging defects, ingot defects

Steel name: Steel

Steel composition in weight %: No data.

Note: Today’s forging industry requires a wide range of raw materials,

all of which must meet certain standards that limit the quality of

the semi-finished products. In addition to imparting a certain

shape and geometric dimensions, the forging process eliminates

defects in the initial semi-finished product as it breaks up

coarse-grained dendritic structures and nonmetallic inclusions. Thus, the final product is characterized both by the inherited

macrostructural nonuniformity of the ingot and by the nonuniformity

which results from plastic deformation. However, cracking

may occur during hot forging of steel ingots originating from the

cast microstructure or unsuitable forging conditions. The intersection

between the hot top (riser) and ingot is a critical region in

which circumferential cracks could form during the primary stages

of forging. The crack then propagates into the ingot and leads to

high crap formation. Fig. 1 shows a typical circumferential crack

that is formed during the open-die forging of a low alloy steel

ingot.

Fig. 2 shows the photograph of the same ingot shown in

Fig. 1 that is successfully hot forged and no crack is formed during

forging. This ingot was cast under constant pouring rate of 7 kg s(-1)

(i.e. the pouring rate in hot top is double compared to the one in

Fig. 1). It confirms that increasing pouring rate in hot top of P64 ingot

resulted in reducing crack susceptibility in the critical intersection

of hot top and mould ingot.

Reference: Not shown in this demonstration version.