Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Machining surface defect - AISI 1215 steel - Machining defects

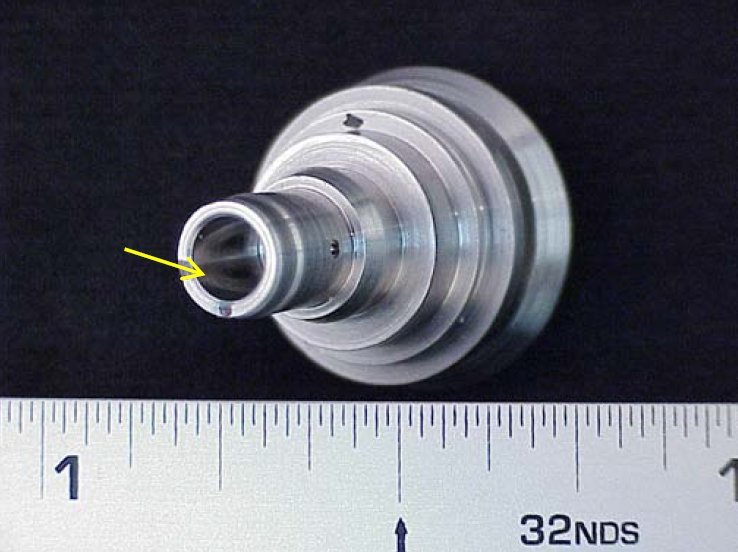

Figure 1: Submitted part with surface defect indication on

the ID surface, denoted by the yellow arrow. 1.5x.

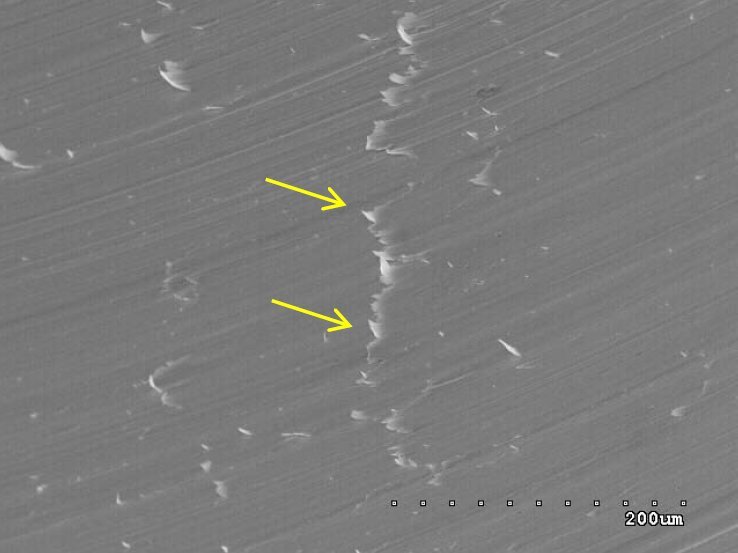

Figure 2: SEM image showing the faint linear defect

indication on the machined ID surface. 10x.

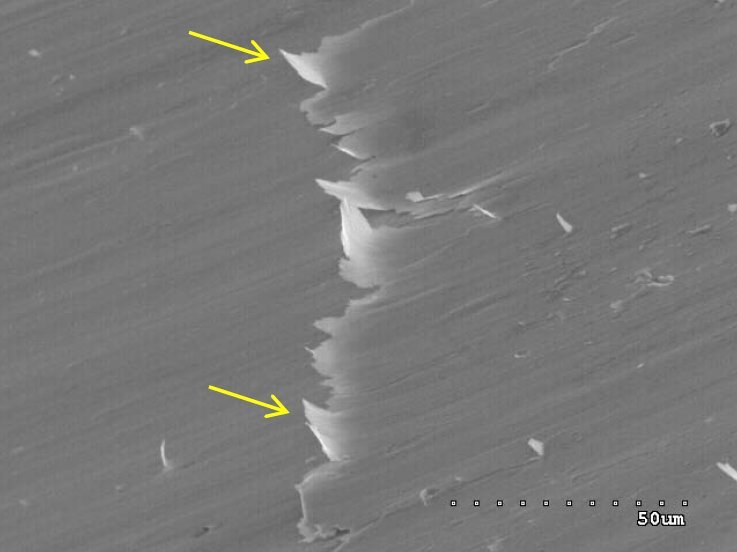

Figure 3: Close-up view of linear defect indication denoted

by the yellow arrow in Figure 2. 165x.

Figure 4: Higher magnification view of Figure 3 showing a

tool mark from the machining operation. 1350x.

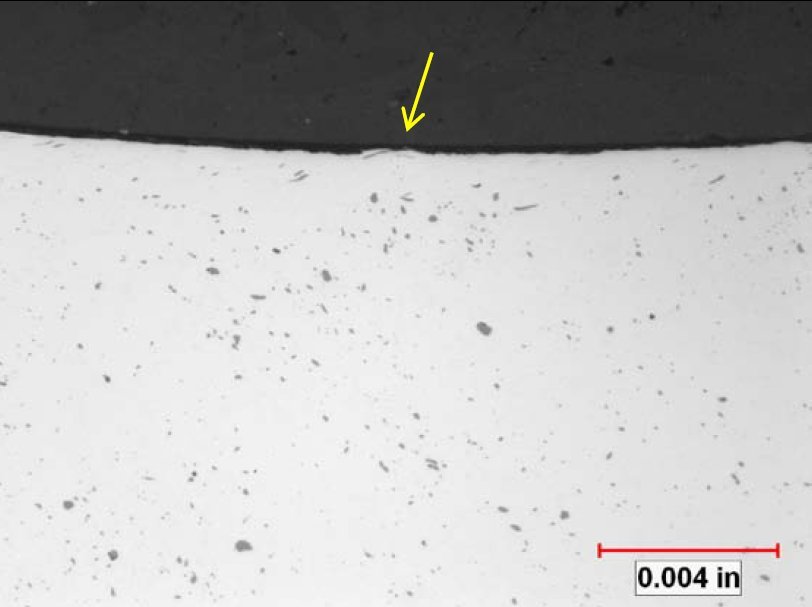

Figure 5: Cross-sectional view of stress crack initiating from .037” deep seam (at arrow).. Mag. 200x.

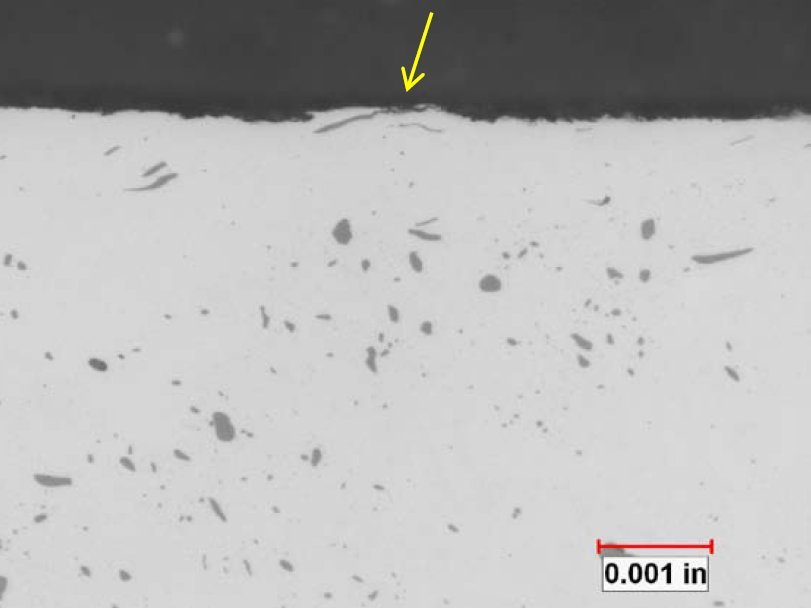

Figure 6: High magnification view of seam profile showing decarburization

and dispersed oxides. Mag. 500x.

Defect name: Surface defect

Record No.: 690

Type of defect (Internal/Surface): Surface

Defect classification: Machining defects

Steel name:

Steel composition in weight %: 0.06% C, 0.96% Mn, 0.02% Si, 0.05% P, 0.31% S, 0.03% Cr, 0.03% Ni, 0.01% Mo, 0.06% Cu.

Note: One cold drawn and machined part exhibiting a linear defect indication on the machined ID surface was submitted to our laboratory for a metallurgical failure analysis service investigation. Our metallurgy experts were requested to determine the source cause of the ID surface defect indication. The material identification is shown in the table below.

Based upon the opinion of our failure analysis lab and the performed examinations, it is our opinion the ID surface of the part contained a faint, intermittent, tool mark that was induced during the machining operation.

No evidence was observed of a pre-existing internal steel defect or inclusion stringer on the ID surface that could have caused the defect indication.

The microstructure as determined by the metal test lab was typical of AISI 1215 steel.

SEM examination of the ID surface revealed a faint, intermittent, linear surface defect indication along the .234” diameter ID surface. (See arrows in Figures 1 - 2).

Examination at higher magnification showed evidence of disturbed metal, most likely from the machining tool (see Figures 3 – 4). No evidence was observed of a pre-existing internal steel defect or inclusion stringer on the ID surface.

Metallographic examination

1. A transverse section removed from the region containing the ID surface defect indication confirmed the presence of a tool mark that was induced during the machining operation. (See arrow in Figures 5 - 6).

2. No evidence was observed of an abnormal inclusion content or any other detrimental internal conditions that could have caused the defect indication.

3. The microstructure consisted of pearlite and grain boundary cementite in a matrix of ferrite, typical of AISI 1215 steel.

Reference: Not shown in this demonstration version.