Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Microbreaks near nonmetallic inclusions after plastic deformation of wheel steel

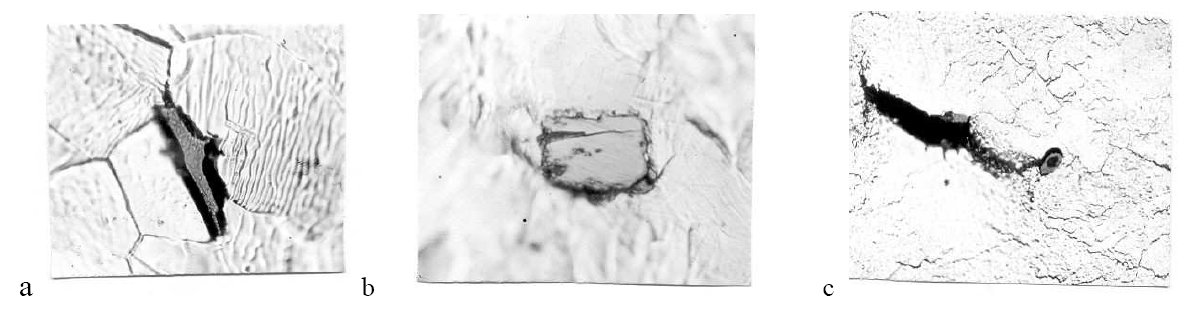

Figure 1: Microbreaks near nonmetallic inclusions after plastic deformation, Mag. 600 X.

Inclusion name: Inclusion

Record No.: 854

Inclusion formula: No data

Inclusion type (Macro/Micro/Nano): No data

Inclusion type (Exogenous/Indigenous): No data

Inclusion classification: No data

Inclusion composition in weight %: No data

Sample: Wheel steel

Steel composition in weight %: No data

Note: It is well known that formation of defects of many types during railway wheels service somehow or other is connected to nonmetallic inclusions in wheel steel.

Microbreakes connected with nonmetallic inclusions have different origin. The first one is “deformational”, the second is “thermal” and the third is “hydrogenous”. The objective

of this work is the study of nature of microbreaking in wheel steel relative to nonmetallics. Mechanisms of microbreaking of all types near different nonmetallics had

been investigated and their influence on safety threshold of railway wheels had been analyzed herein.

Three types of microbreaks of deformable origin observed near nonmetallics were as follows: voids (ductile cracks) – as a result of decohesion along interface inclusion-matrix, cracks in inclusion and matrix near inclusion. Mechanism of microbreaks development is distinguished by the type of inclusion, ratio of cohesive resistance, matrix and interface inclusion/steel matrix and conditions of deformation (Fig. 1).

Voids had been observed near rigid inclusions of such oxides as Al2O3, MnO x Al2O3 at all temperatures. Such silicates as MnO x SiO2, FeO x SiO2 at temperature ranging from 25 C to 900 C are inductile and brittle cracks occur in them. At higher temperatures silicates are ductile and cracks in them are occurred more rarely. Such sulfides as FeS, (Fe, Mn)S are ductile at all temperatures and cracks in them had been observed in the range of 25-600 C, but voids, occurring as a consequence of difference between plasticity of inclusions and steel matrix, had been observed at different temperatures. It should be emphasized that sulfides had been fused at temperatures 1030-1050 C and nature of voids had not been deformable, but other nature; at that, deformation localization of matrix near inclusion became sharper. Each type of microbreaks occurred while reaching certain deformation level – critical epsilon(kp), which value depends on temperature and connected with plasticity level of system inclusion-matrix. It is significant that during temperature raising epsilon(kp) value is increasing for all types of inclusions and microbreaks, but for sulfides, where at temperatures higher than 1030 C red brittleness occur as a result of inclusion fuse, epsilon(kp) value is decreasing sharply. Microbreaking growth rate is defined by its nature and temperature.

Additional links: Not shown in this demo version.

Reference: Not shown in this demo version.