Alphabetical Index

Chemical Composition

Keyword Search

Named Inclusions

Steel Index

Exogenous Inclusions

Indigenous Inclusions

Macro Inclusions

Micro Inclusions

Nano Inclusions

Iron Oxide Inclusions

Nitride Inclusions

Oxide Inclusions

Phosphide Inclusions

Silicate Inclusions

Spinel Inclusions

Sulfide Inclusions

Refractory Inclusions

Slag Inclusions

Figure Browser

Help

Contact Us

Home

Complex inclusions in C-Mn-B steel

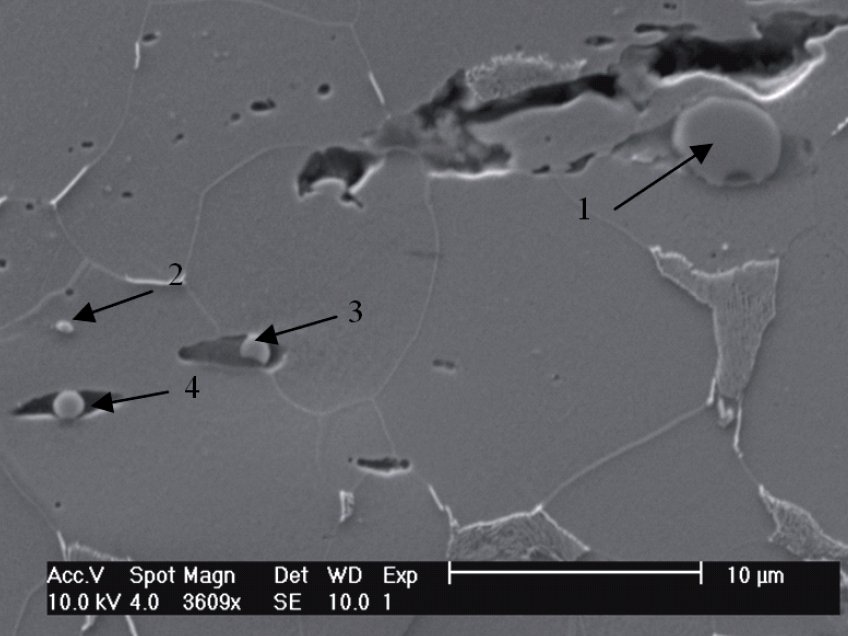

Figure 1: Inclusions in the sample neck (sample deformed at 900 C with strain rate 6.5s-1). SEM, scale bar: 10 µm.

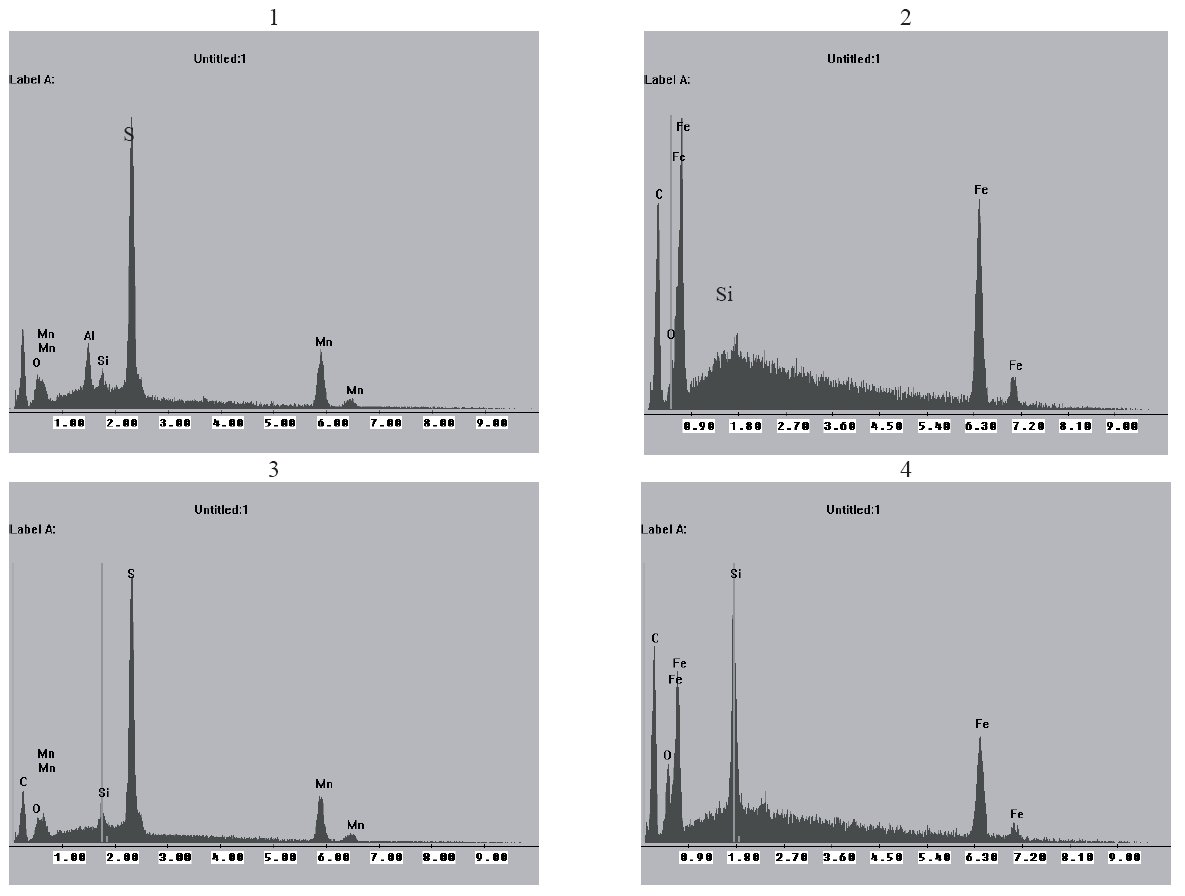

Figure 1: The EDX spectra of inclusions showed in upper Fig., taken with 10 kV energy.

Inclusion name: Complex inclusion

Record No.: 862

Inclusion formula: No data

Inclusion type (Macro/Micro/Nano): Micro

Inclusion type (Exogenous/Indigenous): Indigenous

Inclusion classification: Sulfide, oxide

Inclusion composition in weight %: See the EDX spectra

Sample: C-Mn-B steel

Steel composition in weight %: 0.10% C, 0.47% Mn, 0.08% Si, 0.014% P, 0.023% S, 0.08% Cr, 0.05% NI, 0.17% Cu, 0.014% Mo, 0.009% Sn, 0.006% B, 0.009% N.

Note: Microstructure investigations after hot deformation carried out on the low carbon-manganese steel with addition of boron was presented in this work. The non-metallic inclusion influence on the microstructure and type of crack mechanism was shown.

In Fig. 1 the etched surface with long inclusions is shown. In Fig. 1 the whole inclusion is a complex of many elements like Al, Si, Ca, Mn, S which can create oxides and other

phases. They formed a very long inclusion ~24 µm length. The void around it is not much longer. The small voids on the surface used to contain inclusions but probably they were removed during polishing. All analyzed inclusions were bigger than 0.5 µm because of the size limitations of the beam in EDX analyses. To determine the chemical composition of inclusions smaller than 0.5 µm, TEM microscopy will be used in the future. Inclusions with bigger diameter than 1 µm occur in the structure in different places e.g.

inside the grains but also at the grain boundary. In the sample neck they are always inside voids, where the influence of deformation occurred.

Additional links: Not shown in this demo version.

Reference: Not shown in this demo version.