Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

A rough substrate surface - Galvanizing - Coating defects

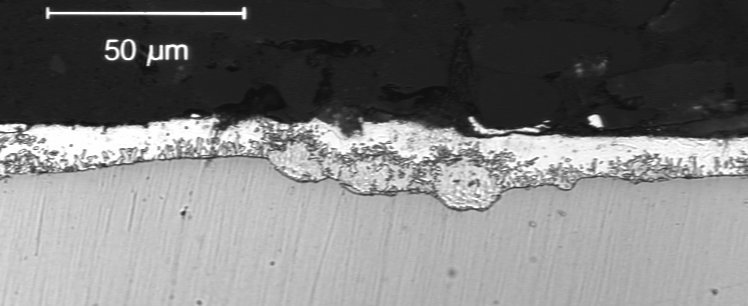

Figure 1: A rough substrate surface results in Zn-Fe alloy outbursts in the coating.

Defect name: Rough substrate surface

Record No.: 1992

Type of defect (Internal/Surface): Internal, surface

Defect classification: Coating defects

Steel name: Steel

Steel composition in weight %: No data.

Note: Although the science and technology of continuous galvanizing have improved significantly

over the years, it is still a challenge to produce defect-free coatings. Studies indicate that

poor substrate surface quality, insufficient strip cleaning, mechanical damage to the substrate

surface due to handling, and inadequate process control are the main causes of coating

defects. The recent introduction of high strength steels makes the production of galvanized

coatings for applications such as exposed autobody panels even more challenging. To

produce high quality zinc-coated strip, galvanizers need to improve quality control of the

incoming strip as well as the continuous galvanizing process.

A rough substrate surface containing iron fines and slivers is prone to the development of

outbursts in the coating. The resultant coating is rough with numerous areas of localized

thick coatings. After being flattened in temper rolling, these areas reflect light differently,

appearing as either dark or bright spots depending on the lighting condition. A typical

sample is shown in Figure 1. Studies indicate that the density of this kind of defect decreases

with increasing coating weight, suggesting that such a defect can be masked by a thick

coating.

Reference: Not shown in this demonstration version.