Alphabetical Index

Keyword Search

Casting Defects

Ingot Defects

Slab Defects

Drawing Defects

Forging Defects

Rolling Defects

Bearing Defects

Coating Defects

Corrosion Defects

Fractography

Heat Treatment Defects

Machining Defects

Other Defects

Pipeline Defects

Polishing Defects

Rail Defects

Tool Steel Defects

Welding Defects

Internal Defects

Surface Defects

Internal + Surface Defects

Contact Us

Help

Home

Centerline segregation - Slab defects

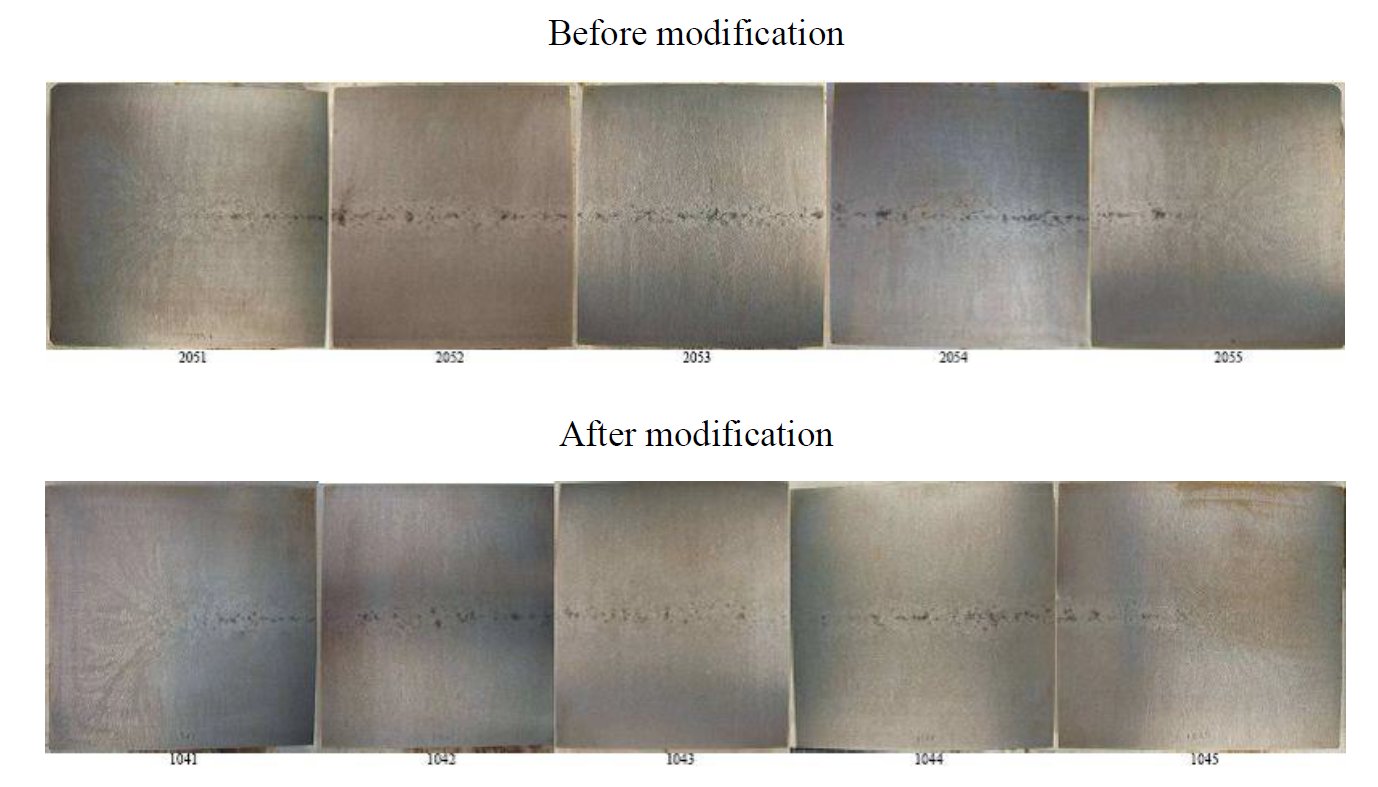

Figure 1: Macroetched cross sections of slabs cast with the original (above) and modified (bottom) roll setting (thickness of slab: 240 mm).

Defect name: Centerline segregation

Record No.: 2705

Type of defect (Internal/Surface): Surface

Defect classification: Slab defects

Steel name: Steel

Steel composition in weight %: No data.

Note: Centerline segregation of slabs relates partly to macrosegregation and partly to the shrinkage of melt, the formation of small shrinkage holes and, occasionally, the formation of inclusions). In continuous casting centerline segregation develops in the middle part of the slab due to solidification and transformation processes, to fluid flow and also to constrained liquid supply, which is necessary for solidification shrinkage compensation. Only enriched melt is present between solid dendrite trunks. Any effect that enhances fluid flow (i.e. cooling conditions, setting of the supporting rolls, bulging between successive rolls, etc.) necessarily results in the flow of the enriched melt, i.e. macrosegregation will form. The possibility of sufficient liquid supply in the mushy area decreases depending on the ratio of solid phase. At the same time the permeability of zigzag channels between dendrite arms also decreases. Lessening the possibility of liquid supply inevitably leads to the formation of shrinkage holes and porosity, which is also

typical of centerline segregation formation.

In order to check the inner quality and the calculation results, samples were cut

from both strands after casting. The samples (containing the whole cross sectional

area) were ground and macroetched by ammonium-persulfate reagent. Pictures of

macroetched samples can be seen in Fig. 1.

Reference: Not shown in this demonstration version.